Electronic waste, or e-waste, is a rapidly growing global issue, and it is expected to worsen with the production of new types of flexible electronics for robotics, wearable devices, health monitors, and other emerging applications, including single-use devices.

A novel type of flexible substrate material developed by researchers at MIT, the University of Utah, and Meta holds the potential to not only recycle materials and components at the end of a device’s life but also enable the scalable manufacturing of more complex multilayer circuits than those provided by existing substrates.

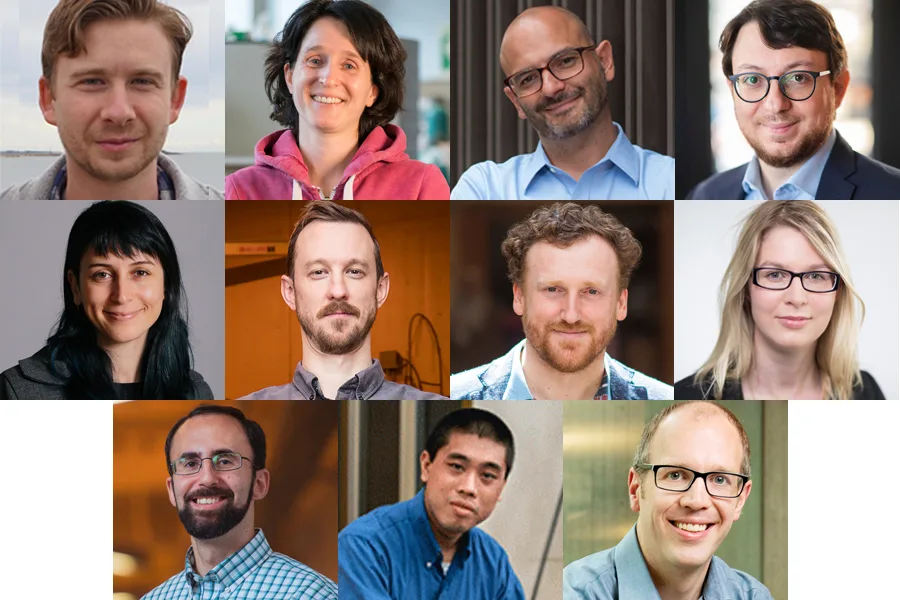

This new material is detailed in a paper published this week in the journal RSC: Applied Polymers by MIT Professor Thomas J. Wallin, University of Utah Professor Chen Wang, and seven other researchers. The paper can be accessed here.

« We recognize that e-waste is a persistent global crisis that will only worsen as we continue to build more devices for the Internet of Things and as the rest of the world develops, » says Wallin, an assistant professor in MIT’s Department of Materials Science and Engineering. To date, much academic research in this field has aimed to develop alternatives to conventional substrates for flexible electronics, which primarily use a polymer known as Kapton, a commercial name for polyimide.

Most of this research has focused on entirely different polymer materials, but « this really ignores the commercial aspect of why people chose the materials they did in the first place, » Wallin explains. Kapton has many advantages, including excellent thermal and insulating properties and immediate raw material availability.

The polyimide market is projected to reach a global market value of $4 billion by 2030. « It’s everywhere, in every electronic device actually, » including parts like the flexible cables that connect various components of your mobile phone or laptop, Wang explains. It is also widely used in aerospace applications due to its high heat tolerance. « It’s a classic material, but it hasn’t been updated in three or four decades, » he says.

However, Kapton is also nearly impossible to melt or dissolve, making it non-recyclable. These same properties also make it more challenging to fabricate circuits in advanced architectures, such as multilayer electronics. The traditional method of making Kapton involves heating the material between 200 and 300 degrees Celsius. « It’s a rather slow process. It takes hours, » Wang says.

The alternative material developed by the team, which is itself a form of polyimide and should therefore be easily compatible with existing manufacturing infrastructure, is a photopolymerizable polymer similar to those currently used by dentists to create durable fillings that harden in seconds with ultraviolet light. Not only is this method of curing the material relatively fast, but it can also work at room temperature.

The new material could serve as a substrate for multilayer circuits, significantly increasing the number of components that can be packed into a small format. Previously, since the Kapton substrate did not melt easily, layers had to be glued together, adding steps and costs to the process. According to Wang, the fact that the new material can be processed at low temperatures while curing very quickly on demand could pave the way for new multilayer devices.

Regarding recyclability, the team introduced subunits into the polymer backbone that can be quickly dissolved by an alcohol and catalyst solution. Then, the precious metals used in the circuits, as well as entire microchips, can be recovered from the solution and reused for new devices.

« We designed the polymer with ester groups in the backbone, » unlike traditional Kapton, Wang explains. These ester groups can be easily broken down by a relatively mild solution that removes the substrate while leaving the rest of the device intact. Wang notes that the University of Utah team has co-founded a company to commercialize the technology.

« We are breaking the polymer down into its original small molecules. We can then collect the expensive electronic components and reuse them, » adds Wallin. « We are all aware of the chip and certain material supply chain shortages. The rare earth minerals contained in these components are very valuable. So we believe there is now a huge economic and environmental incentive to implement these processes to recover these components. »

The research team included Caleb Reese and Grant Musgrave from the University of Utah, as well as Jenn Wong, Wenyang Pan, John Uehlin, Mason Zadan, and Omar Awartani from Meta’s Reality Labs in Redmond, Washington. The work was supported by a startup fund from the Price College of Engineering at the University of Utah.